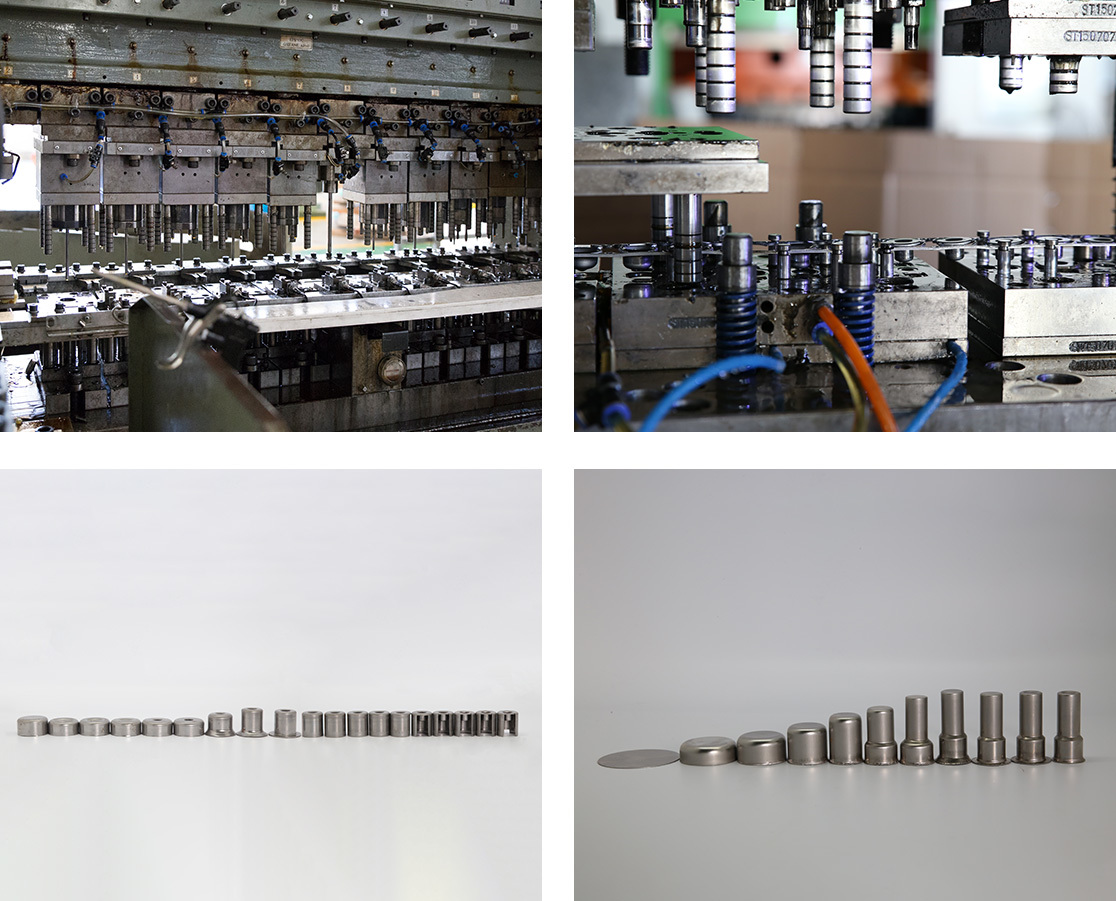

Deep Drawing Technology

Drawing technology refers to the process of cold forming the metal strip into various hollow shaped parts on the premise of ensuring the plastic deformation of the metal material by drawing, pressing and other deformation methods.Deep drawing technology is a kind of high-tech process of economy and environmental protection. Even if the size is as small as 1mm diameter and the wall is as thin as 0.1mm, we can also draw. It has a high efficiency of material utilization, up to more than 70%. At the same time, using high efficiency die and stamping equipment, greatly reducing the manufacturing cost and environmental burden. Of course, compared with the traditional turning, the efficiency is greatly improved. More importantly, deep drawing technology is a kind of cold deformation of metal, which increases the mechanical properties of products to a certain extent, such as surface hardness. Yuqin uses progressive and transfer tooling to produce hundreds of different parts. Materials used include: carbon steel, stainless steel, copper alloy, nickel alloy, aluminum alloy, Inconel, Kovar and other special materials. Our deep drawing press is mainly imported equipment, progressive drawing machine from 60 tons to 300 tons. The transfer presses are from 45 tons to 300 tons. It totally have 15 deep drawing and stamping production lines (September 2019). With the rapid development of business, our equipment is added at a rate of 30% every year.